DTF white ink heat transfer printing is an advanced printing technology that uses a DTF printer to print patterns on DTF PET film and then transfer the patterns to the fabric. As we all know, DTF printers break the limitations of fabrics and can print on all types of fabrics. Among all fabrics, cotton, polyester, denim, silk, leather and nylon are the most popular fabrics in the DTF printing industry.

Cotton Fabric

Cotton fabric is made of cotton and produced by spinning technology. It has the following advantages:

Cotton fabric is suitable for shirts, dresses, blouses, sweaters, underwear, socks, sheets, blankets, bags, jeans and skirts, etc. Different from DTG printing, DTF printing does not require any pre-processing steps before printing, and the pattern can be quickly printed on the fabric, saving a lot of time and cost.

Polyester Fiber

Polyester is a chemical fiber clothing fabric that is widely used in daily life, such as sportswear, casual wear, swimsuits, umbrellas, raincoats, tents, bags, etc. Polyester fabric has the characteristics of high elastic recovery ability. Therefore, it has strong durability and wrinkle resistance. In addition, polyester also has excellent heat resistance and light resistance. Acids and alkalis have no effect on polyester, making polyester unaffected by mold and insects. Sublimation printing can also be applied to polyester fabrics, but it is limited by light colors, and it is not as practical as DTF printing that can print all colors.

Denim

Denim is a thicker twill cotton fabric with a yarn-dyed surface. Initially, denim was only blue and used as a canvas. But with the development of technology, denim has different uses, such as jeans, dresses, coats, bags, etc. The touch of denim is different, some are soft, some are hard, some are rough, and some are delicate. DTF printing is widely used on different types of denim, and the printed patterns are clear and wear-resistant.

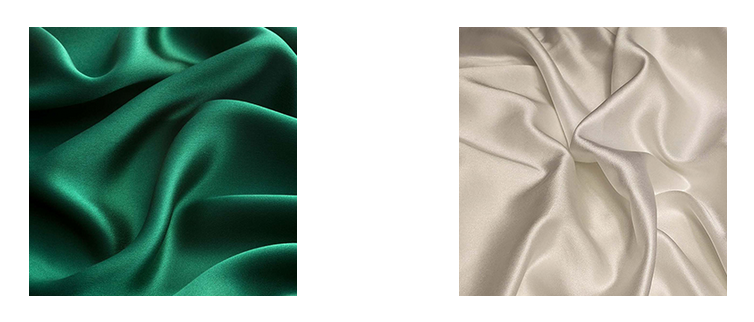

Silk

Silk is a kind of protein fiber, including mulberry silk, tussah silk, castor silk and cassava silk. It is usually used to produce shirts, pajamas, dresses, sheets, bedspreads, pillowcases and hair bands. Items made of silk are very soft, smooth and give people a touch of feeling. DTF white ink heat transfer machine makes silk products more gorgeous without damaging the material itself.

Leather

In recent years, leather fabrics have become very popular in the fashion industry. Leather fabrics on the market are generally divided into three types: genuine leather, recycled leather, and PU/PVC leather. Clothes made of leather fabrics look elegant and luxurious. They are also very light and warm. Currently, leather fabrics are often used to produce bags, belts, leather boots, wallets, leather jackets, and leather skirts. Because the DTF printing process involves high-temperature transfer technology, the leather needs to be able to withstand a certain temperature without deformation or damage. Genuine leather, due to its natural high-temperature resistance, is an ideal choice for DTF printing on leather applications.

Nylon

As the world’s first synthetic fiber, nylon has a wide range of uses in various industries with its excellent performance and abundant raw material resources. In terms of fastness and abrasion resistance, nylon performs best among all fabric fibers. In addition, nylon also has amazing durability, good elasticity and elastic recovery. Today, nylon is often used in work clothes, sports bags, school bags, handbags, etc.

Since DTF printing is suitable for a variety of materials, it is a cost-effective choice for printing companies. In addition, DTF printed patterns have excellent durability. They will not wear out easily. Gotocolor has been committed to providing customers with better quality and more efficient printing printers, looking for more partners, and providing more help for customers’ business. Contact us get the latest price list about the DTF printer.