Do you know the difference between DTF and DTG?

The terms “DTF printer” and “DTG printer” can be confusing due to their similarity in acronym, but they refer to different technologies:

Goto color DTF printer

– Process : DTF printing involves printing designs onto a special release film using a printer with solvent-based or eco-solvent ink.

– Application : The printed design is then transferred from the film onto the garment using a heat press.

– Materials : This method is suitable for printing on various types of fabrics, including cotton, polyester, blends, and even non-textile surfaces like leather.

DTF printing not only available for white background but also dark back ground .

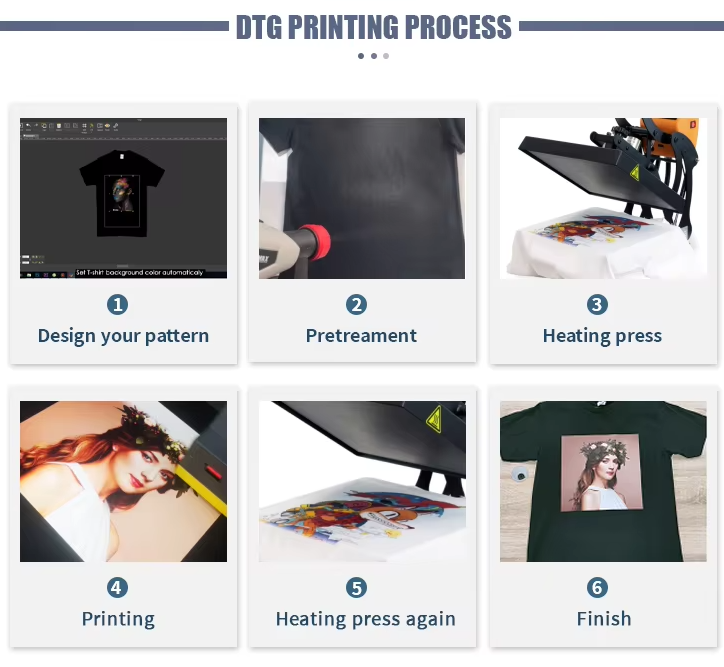

– Process : DTG printing directly applies ink onto the fabric of a garment using a specialized inkjet printer.

– Application : The printer sprays water-based inks directly onto the garment, creating the desired design.

– Materials : DTG printing is best suited for cotton and other natural fabrics, as well as blends that are primarily cotton.

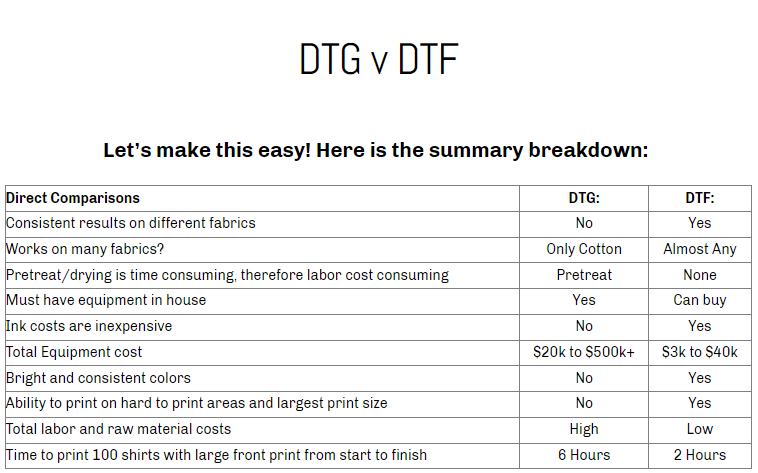

Key Differences :

– Printing Method : DTF printers use a film transfer method, while DTG printers directly print onto the garment fabric.

– Inks : DTF printers typically use solvent-based or eco-solvent inks for printing on the film, whereas DTG printers use water-based textile inks for direct application on garments.

– Material Compatibility : DTF can print on a wider variety of materials, including non-textile surfaces, whereas DTG is primarily used for cotton and cotton-blend fabrics.

In summary, the main distinction lies in the printing process (film transfer vs. direct application) and the type of ink used, which determines the materials each printer can effectively print on.